Academic | Group work | 2018

Professor: Alexander Kitchin | Group members: Cem Akgun, Adriana Sosa

Professor: Alexander Kitchin | Group members: Cem Akgun, Adriana Sosa

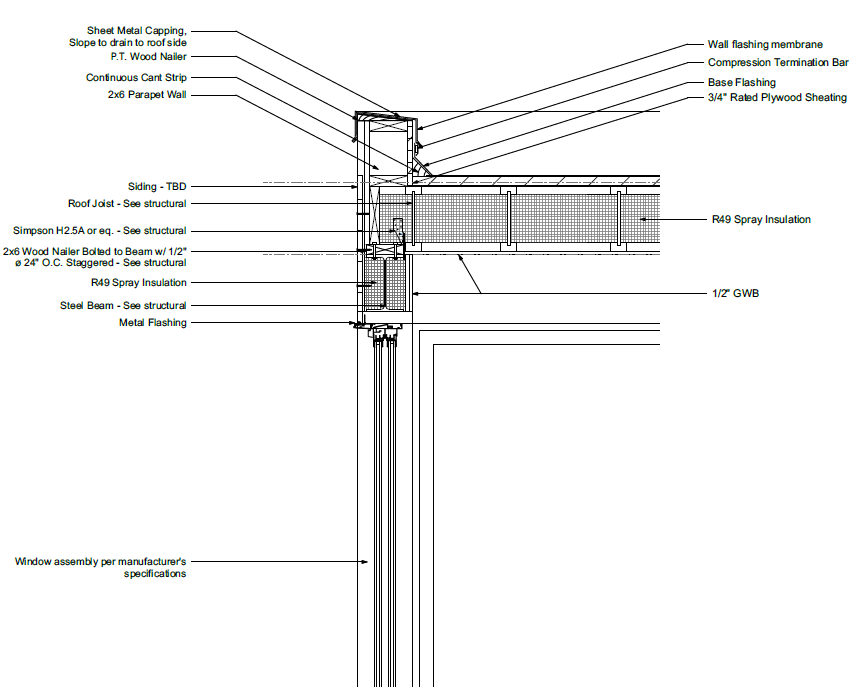

This concrete chair was casted with Ultra-High Performance Concrete. The formwork was created with wood, copper pipes, metal rods and foam shaped by CNC routing. The copper pipes and metal rods allow this chair to be hung in various settings with different weaving methods. The formwork, made mostly out of CNC routed foam, can be re-created in different sizes and thicknesses, by using different curves connected to one specific Grasshopper definition. Fiber-reinforced concrete was essential in casting a durable, lightweight, thin chair, with no need for rebar. The process photos show the basic steps that were essential in creating the formwork. “Woven Concrete” is just one product of a system that can help customize and mass produce concrete furniture.

EXPLODED AXON OF FORMWORK ASSEMBLY

FORMWORK ASSEMBLY & CONCRETE POUR

CNC MILLED FOAM