Academic | Group work | 2023

Professor: Robert Stuart-Smith | Group members: Cem Akgun, Aisha Alshehri, Adhityan Anbumozhi, Mahsa Masalegoo

Professor: Robert Stuart-Smith | Group members: Cem Akgun, Aisha Alshehri, Adhityan Anbumozhi, Mahsa Masalegoo

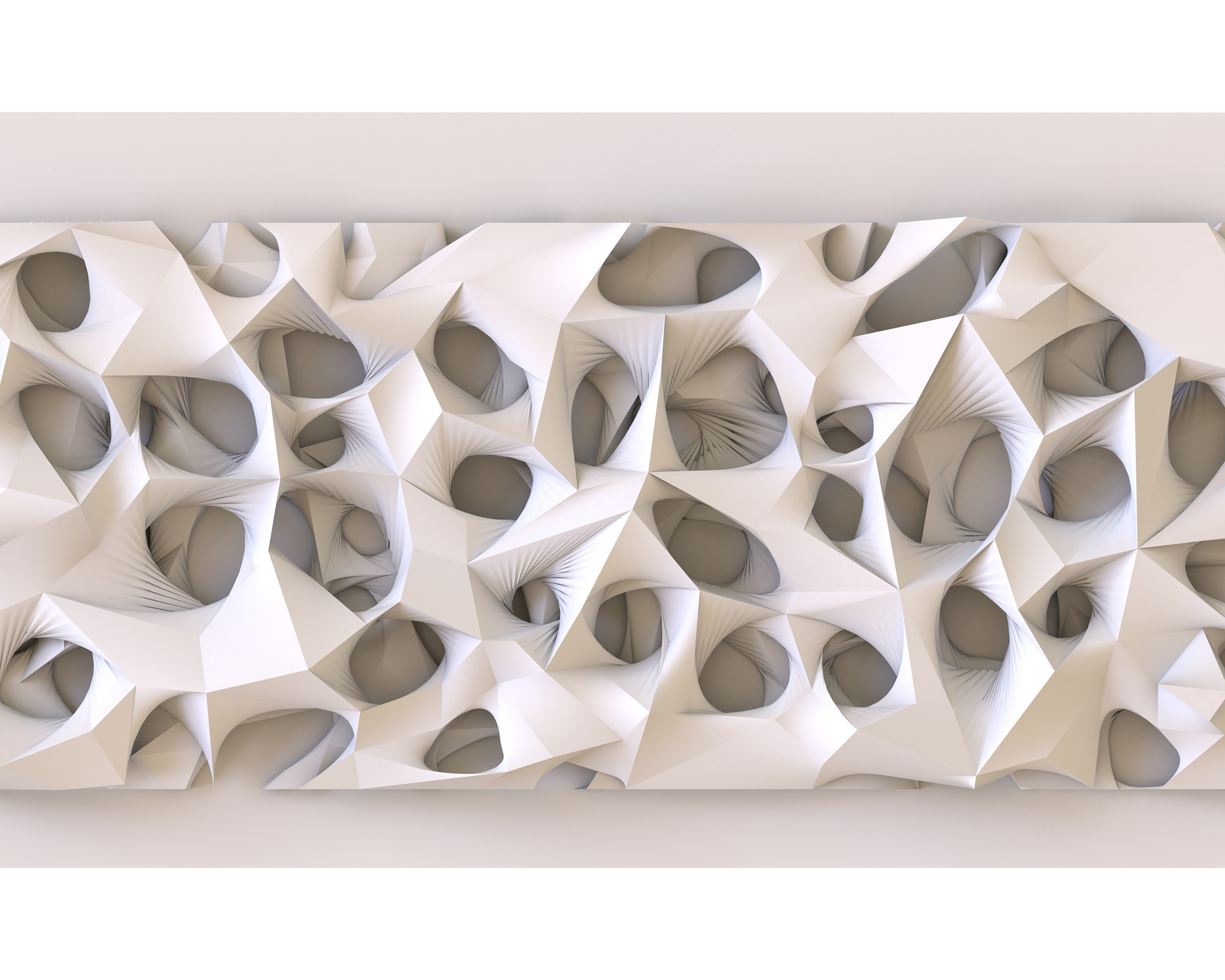

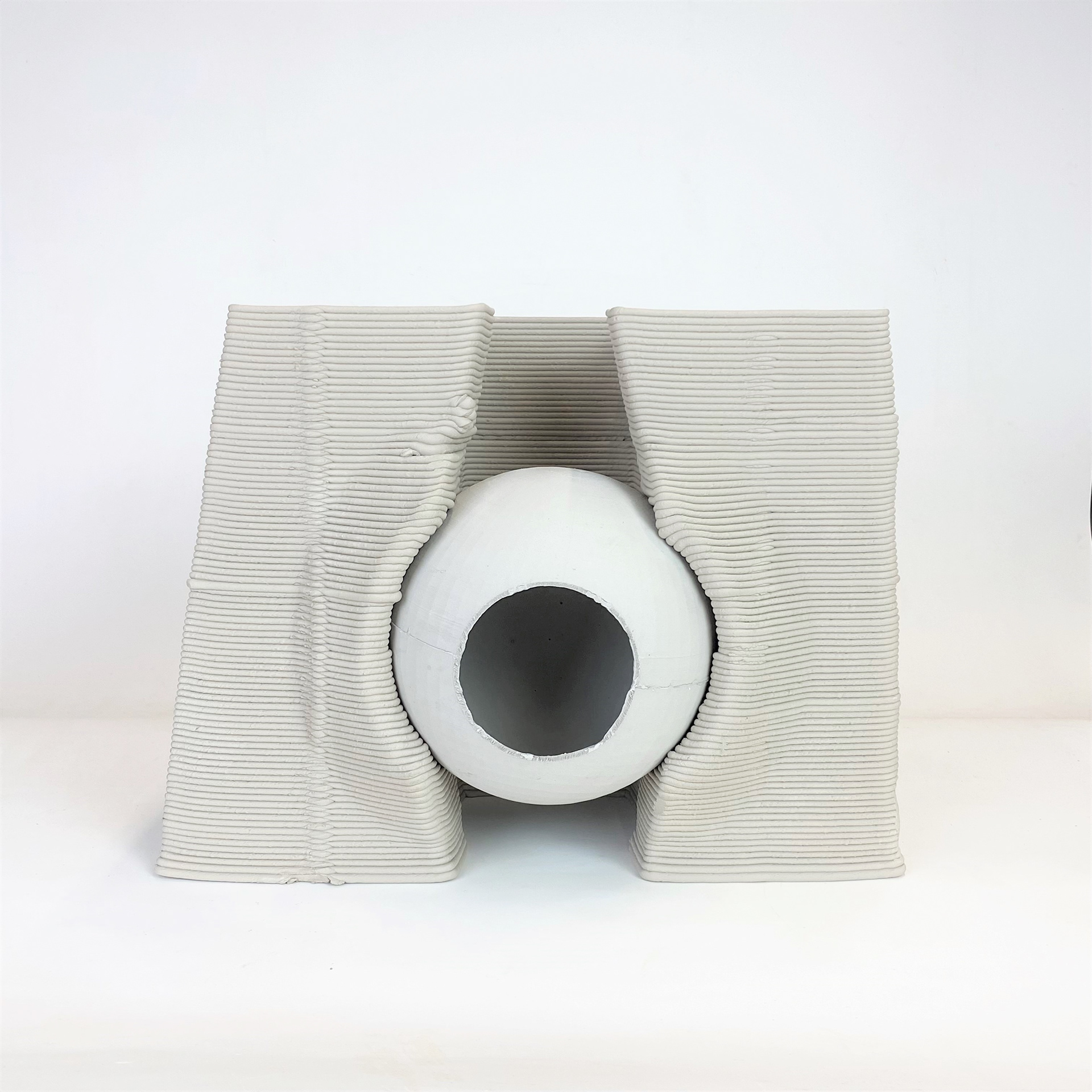

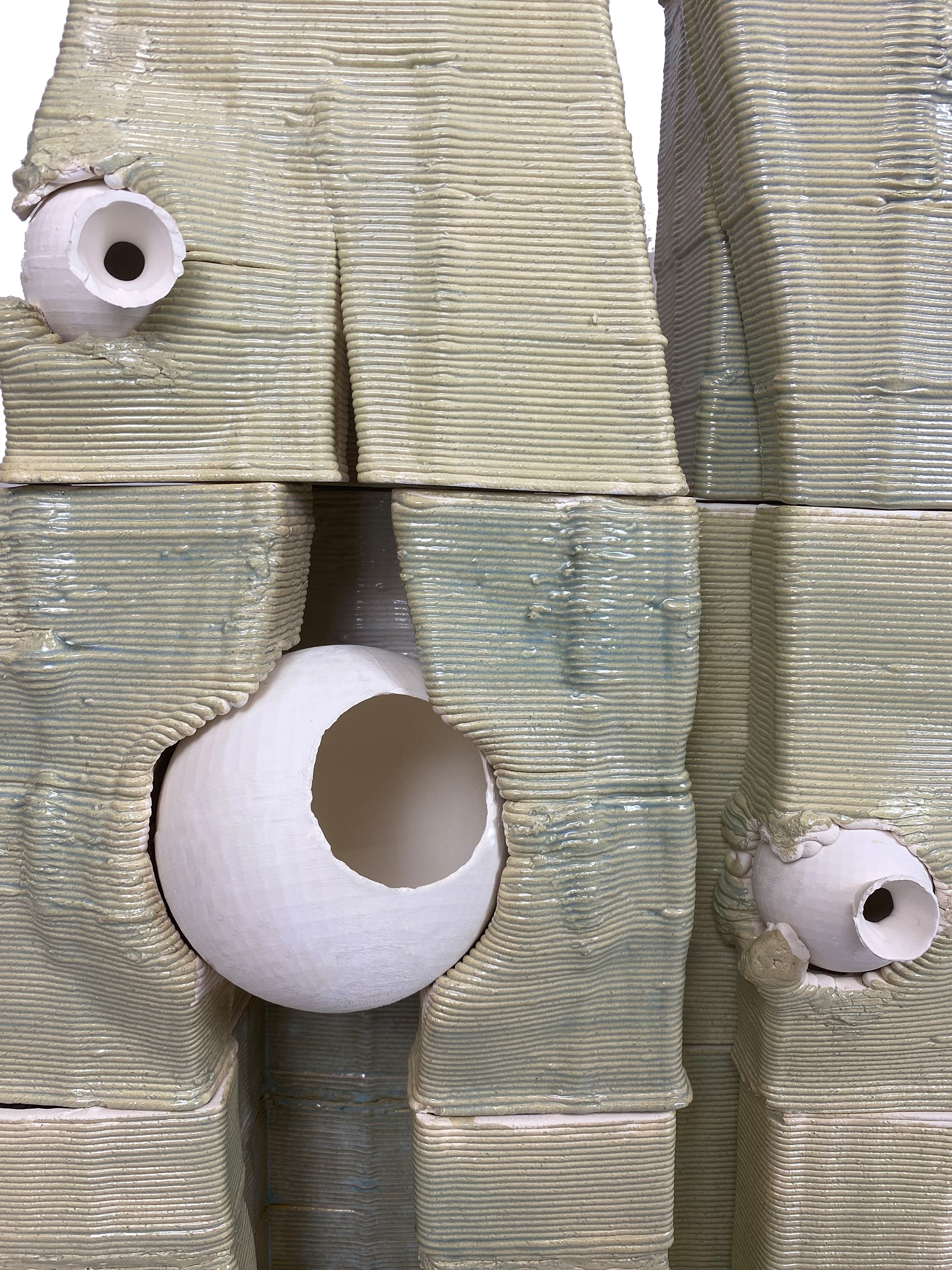

This semester-long studio project explores the robotic fabrication of architectural ceramic components by developing a hybrid manufacturing workflow for a building façade. The research builds upon previous studies on ceramic fabrication methods, robotic additive manufacturing (RAM), and large-scale industrial manufacturing. We investigated two traditional and innovative clay fabrication methods, slip casting and robotic additive manufacturing, in order to create a semi-autonomous workflow that produces customized ceramic assemblies with embedded elements.

In our façade prototype, we successfully combined these methods while incorporating rotational functionality to slip-cast elements. Early experiments demonstrated that by embedding bone-dry slip-cast elements between clay 3D printed parts during the robotic fabrication process, these elements could rotate due to differing shrinkage rates after firing. The inclusion of rotatable spheres enables rainwater collection, facilitating temperature control of the façade. Additionally, the surface porosities create a habitable environment for specific animals, such as birds, offering a vertical living space for various species.

FACADE PROTOTYPE

ROTATABLE SLIP-CAST ELEMENTS

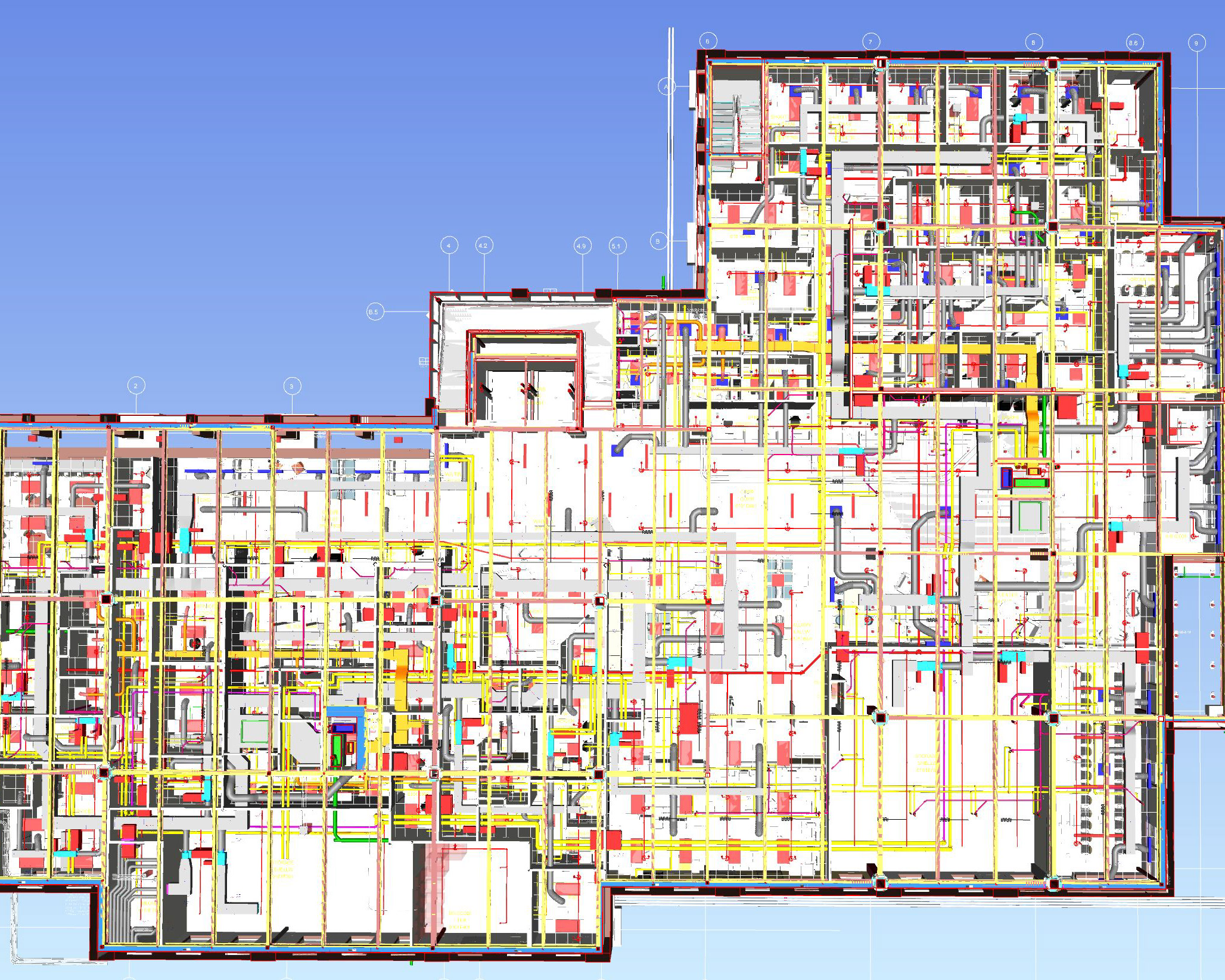

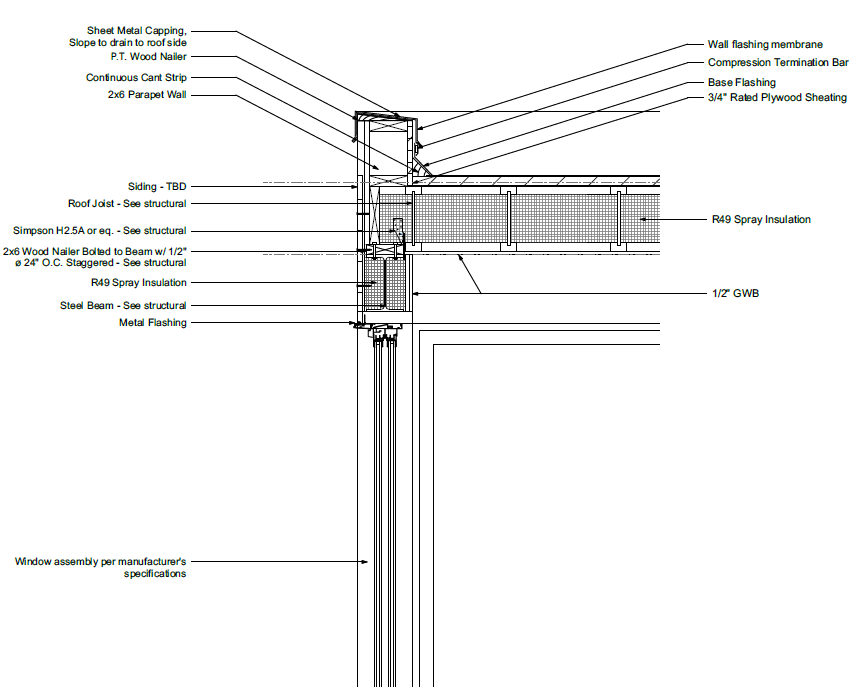

BUILDING FACADE PROPOSAL

EARLY EXPERIMENTS

SLIP CASTING PROCESS & SHRINKAGE FINDING

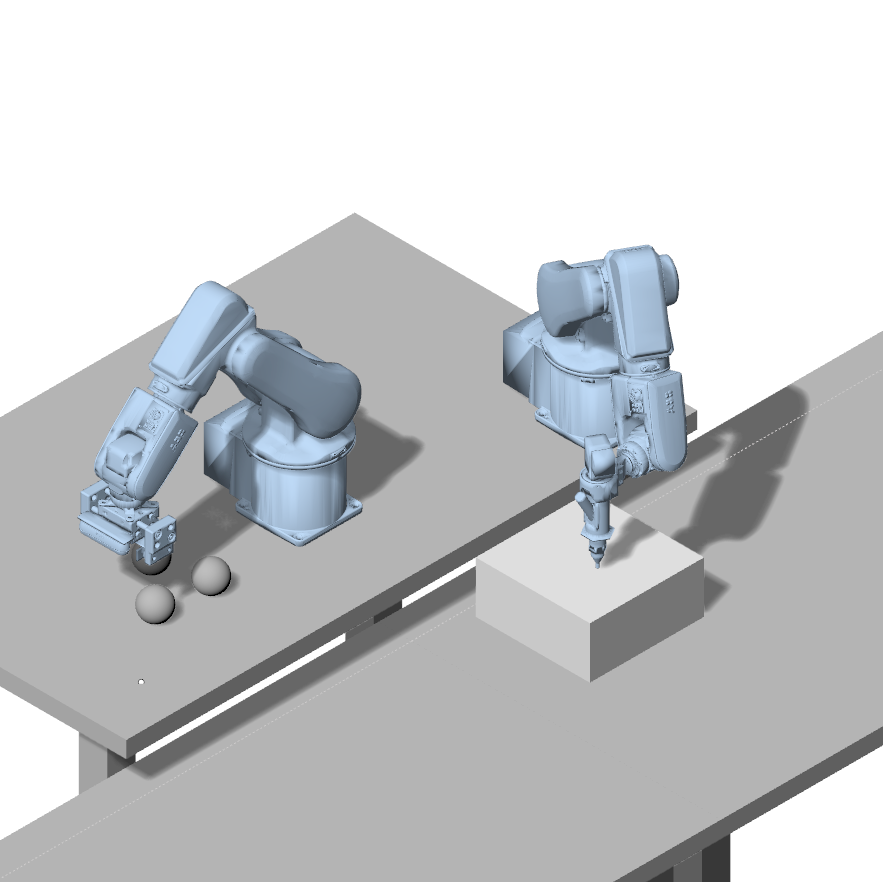

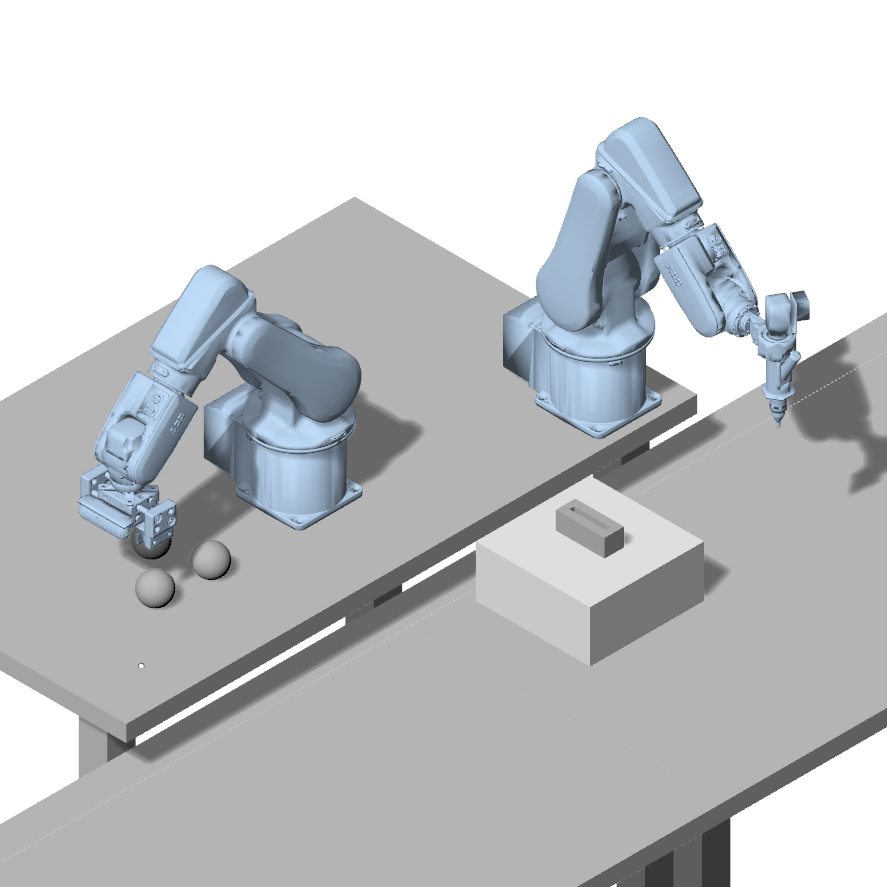

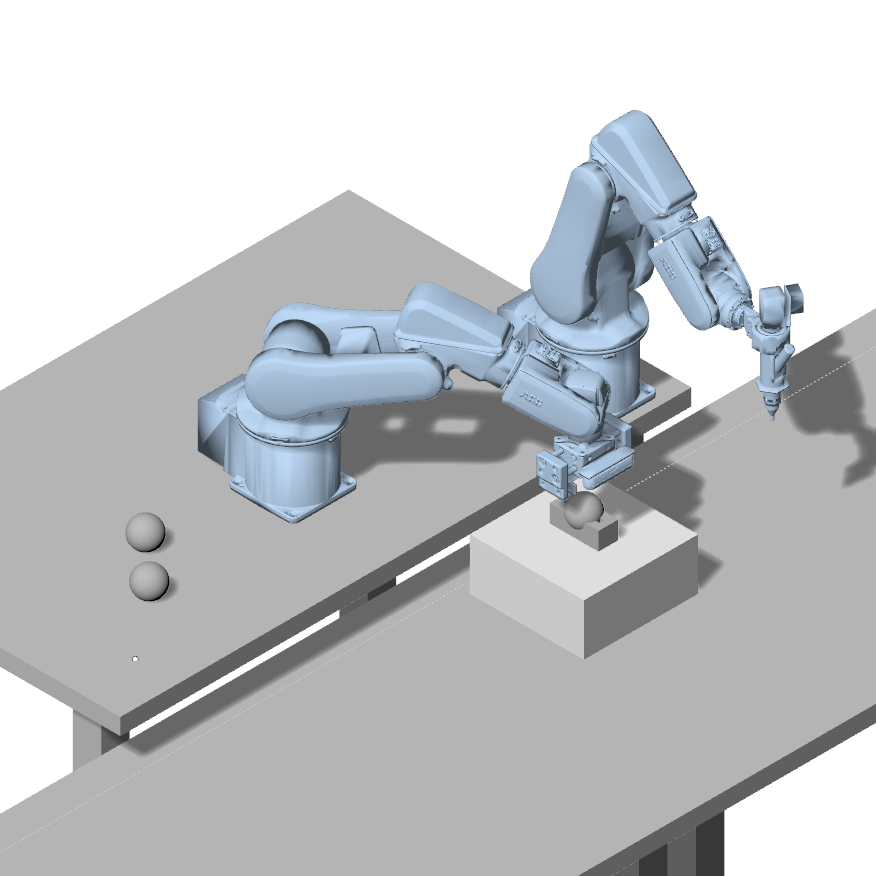

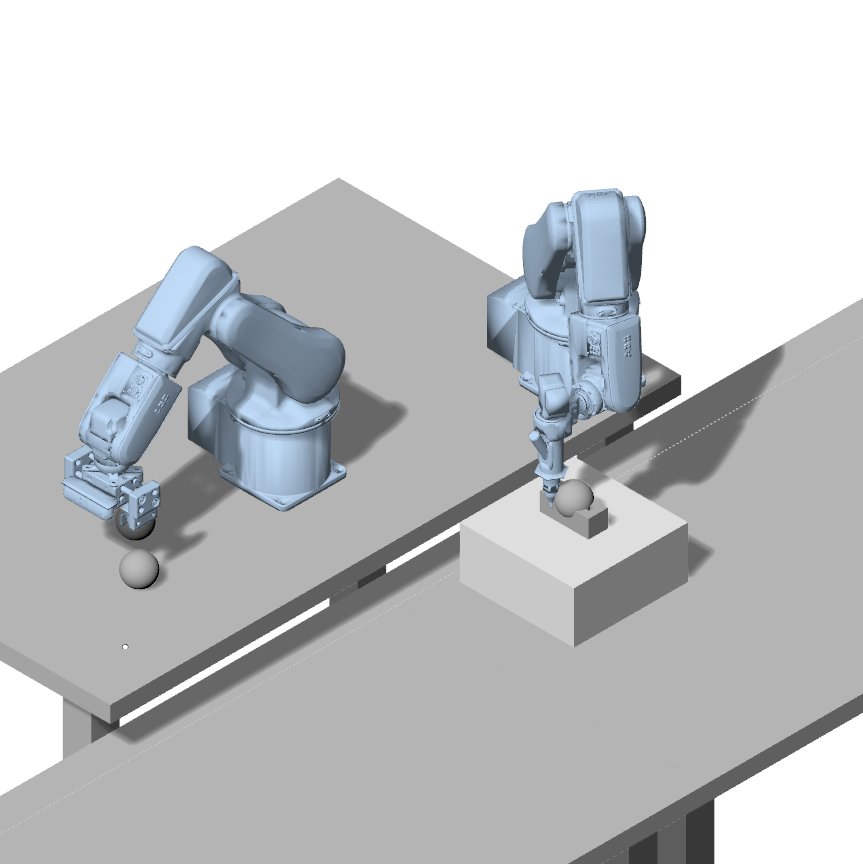

LARGE SCALE ROBOTIC FABRICATION PROCESS

USING REALSENSE TECHNOLOGY & PICK AND PLACE

FINAL PROTOTYPE